hazardous materials diamond sets the stage for this enthralling narrative, offering readers a glimpse into a story that is rich in detail with layers of color, numbers, and symbols that speak volumes about chemical safety. Whether you’ve seen it on the side of a truck, a warehouse door, or a chemical container, this iconic diamond is more than just a colorful sign—it’s a vital tool that keeps workplaces and communities safe.

Developed to provide quick and consistent information, the hazardous materials diamond is a universal system designed to alert emergency responders and workers to potential dangers posed by chemicals and materials. Its clever use of color coding and numerical ratings allows anyone, from seasoned professionals to first-time viewers, to quickly identify risks such as flammability, health hazards, reactivity, and special precautions. The diamond’s enduring presence across industries highlights its essential role in preventing accidents and guiding safe emergency responses.

Hazardous Materials Diamond: Purpose, Structure, and Impact in Safety

The hazardous materials diamond is a widely recognized visual tool used to quickly convey important safety information about chemical hazards. Developed to support first responders, workers, and safety personnel, this diamond-shaped label provides a standardized way to communicate the dangers associated with various substances. Its use has become essential in chemical safety, helping to reduce risks and improve emergency response effectiveness.

First introduced by the National Fire Protection Association (NFPA), the hazardous materials diamond is sometimes called the NFPA diamond, fire diamond, or chemical hazard diamond. Over time, it has become a staple in safety programs across manufacturing, laboratory, and transportation industries, as well as public and emergency response facilities.

Purpose and Origin of the Hazardous Materials Diamond

The hazardous materials diamond was created to address the critical need for fast, clear, and consistent hazard communication. Before its existence, emergency responders and workers often had difficulty quickly identifying chemical dangers during incidents. The NFPA designed the diamond to provide key hazard information at a glance, allowing for more informed and safer responses.

This tool plays a vital role in chemical safety programs and regulatory compliance. It supports decision-making during spills, fires, and other emergencies, helping to minimize risk to people, property, and the environment. Its widespread adoption has standardized hazard communication in workplaces across North America and beyond.

Common Names and Alternative References, Hazardous materials diamond

The hazardous materials diamond is known by several other names, including:

- NFPA Diamond

- Fire Diamond

- Chemical Hazard Diamond

- Hazard Identification Diamond

These names are often used interchangeably in safety training materials, official documentation, and regulatory guidelines.

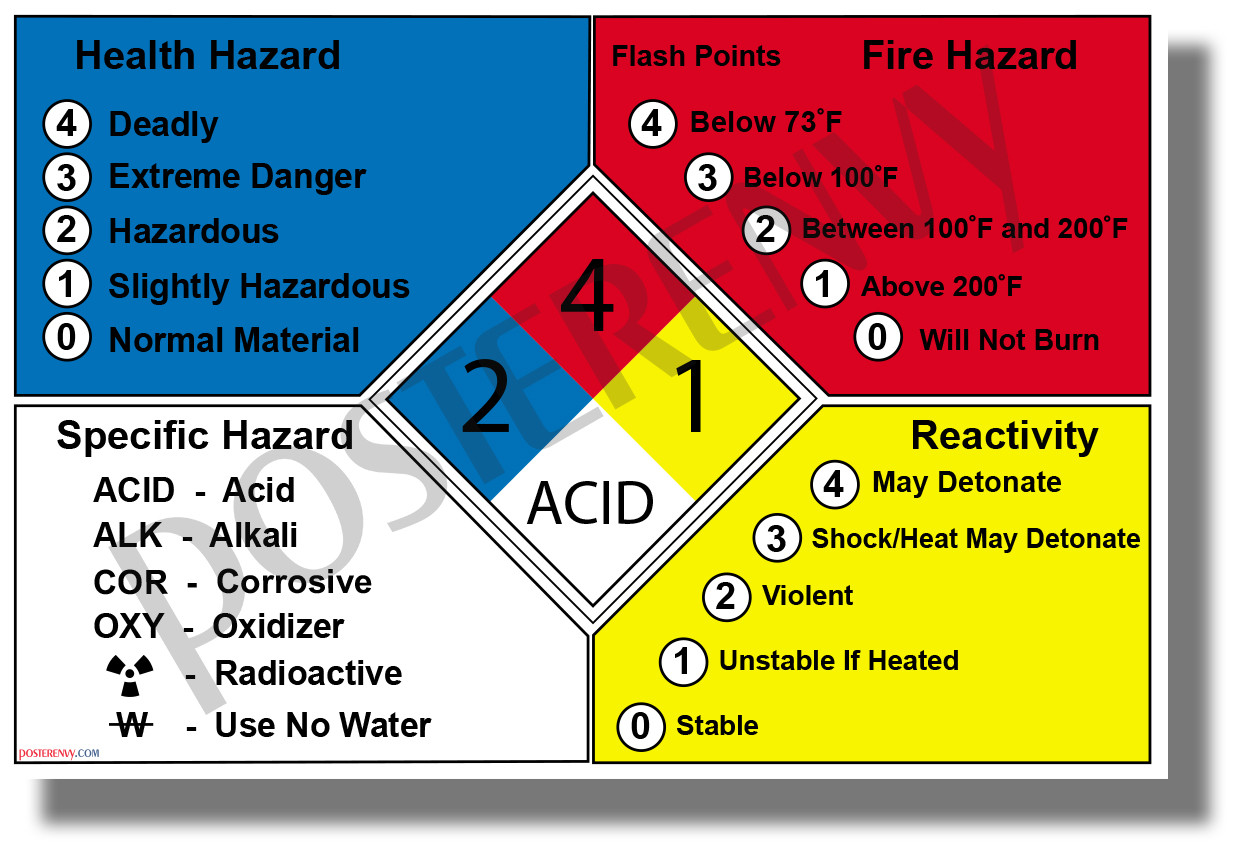

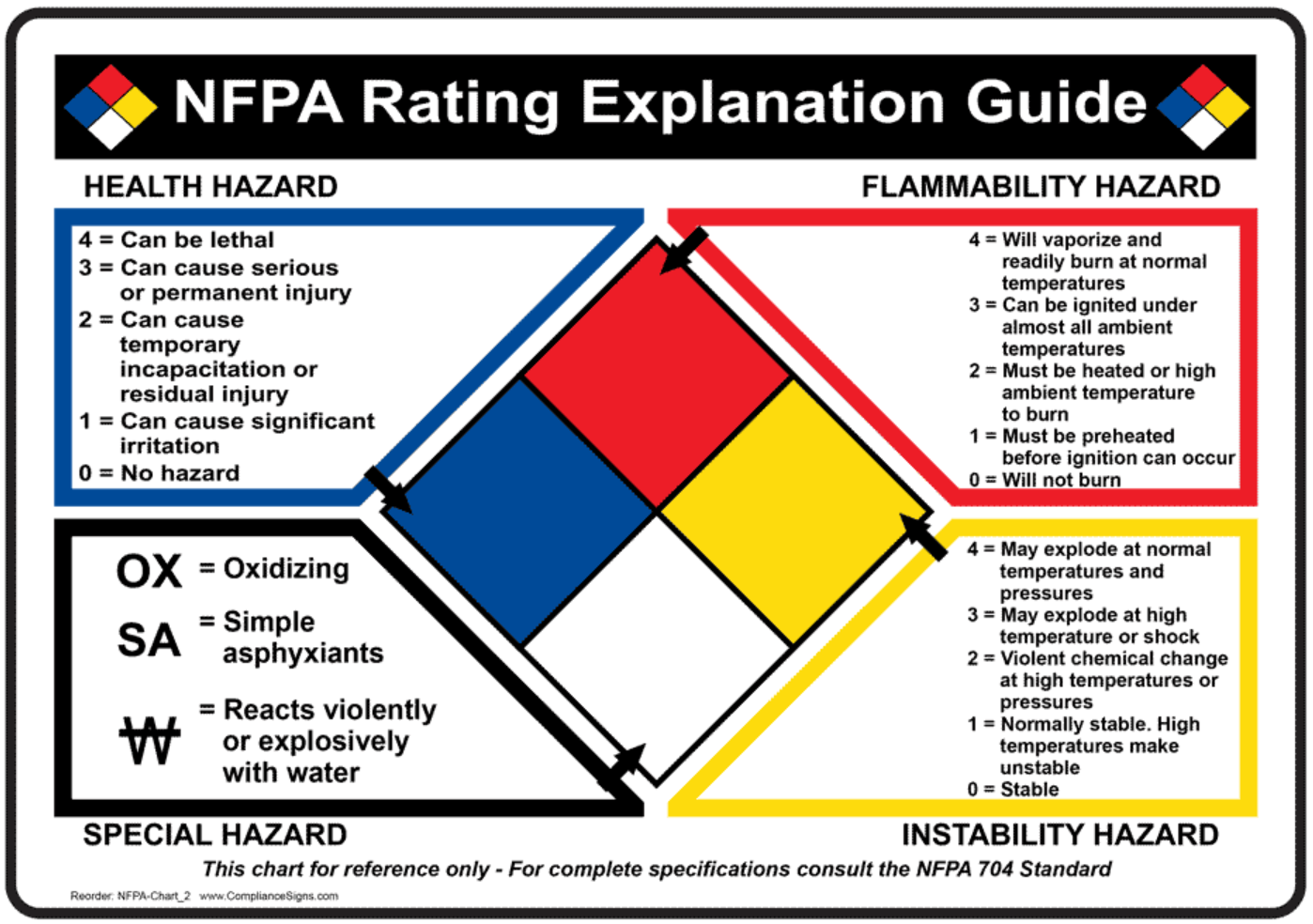

Structure and Color Coding of the Hazardous Materials Diamond

The diamond is divided into four quadrants, each assigned a specific color and representing a different type of hazard. This structured approach ensures that anyone familiar with the system can immediately understand the risks associated with a substance just by looking at the diamond.

Color Meaning and Quadrant Significance

Each color on the diamond has a specific purpose:

- Blue (Left): Health hazards

- Red (Top): Flammability hazards

- Yellow (Right): Instability/reactivity hazards

- White (Bottom): Special or specific hazards

The diamond’s distinctive shape and arrangement allow for quick recognition and easy placement on labels, containers, and facility signage.

| Color | Position | Hazard Type | Description |

|---|---|---|---|

| Blue | Left | Health | Risks to health from exposure (toxicity, irritation, long-term effects) |

| Red | Top | Flammability | Potential for material to catch fire or combust |

| Yellow | Right | Instability/Reactivity | Likelihood of chemical changes or explosions under certain conditions |

| White | Bottom | Special Hazards | Additional, non-standard risks (e.g., reacts with water, oxidizer) |

The diamond’s arrangement is designed for intuitive reading and ensures that all critical information is visible at a glance.

Hazard Ratings and Numbering System

Within the blue, red, and yellow quadrants, a number from 0 to 4 rates the severity of the hazard—0 meaning minimal hazard and 4 indicating extreme danger. This system allows personnel to gauge the risk level immediately and take appropriate precautions.

Understanding the Rating Scale (0-4)

Each number in the three main quadrants signifies the degree of hazard:

- 0 – Minimal (no significant hazard)

- 1 – Slight (minor hazard under emergency conditions)

- 2 – Moderate (temporary or moderate hazard)

- 3 – Serious (major hazard, requires special handling)

- 4 – Severe (life-threatening or extreme hazard)

Sample Hazard Rating Scenarios

These examples illustrate how various chemicals might be rated for quick reference:

| Color | Hazard Example | Rating | Interpretation |

|---|---|---|---|

| Red | Gasoline | 3 | Highly flammable; ignites easily with spark or flame |

| Blue | Ammonia | 2 | Can cause irritation or illness with exposure |

| Yellow | Hydrogen peroxide (concentrated) | 3 | Severe reactivity; may detonate if shocked or heated |

| Blue | Water | 0 | No health hazard under normal use |

The difference between high and low hazard ratings is crucial for daily operations and emergency planning. For instance, a 4 in the red quadrant signals the need for strict fire controls, while a 0 indicates minimal concern for ignition.

Comparing High and Low Hazard Ratings

High ratings (3-4) demand immediate attention and significant protective measures, whereas low ratings (0-1) may only require standard precautions.

- Health (Blue): 4 = Deadly toxicity, 0 = No hazard

- Flammability (Red): 4 = Flash point below 73°F, 0 = Will not burn

- Instability (Yellow): 4 = May detonate, 0 = Stable under fire conditions

Special Precautions and Symbols in the White Diamond

The white quadrant of the hazardous materials diamond is reserved for special hazards that don’t fit into the standard health, flammability, or instability categories. This section can include a variety of symbols or codes that communicate additional risks requiring specific attention.

Common Symbols and Their Meanings

Symbols in the white diamond are shorthand for critical precautions, alerting emergency personnel to unique dangers.

- OX – Material is an oxidizer, which can intensify fires

- W̶ (with a line through it) – Reacts dangerously with water

- SA – Simple Asphyxiant Gas (e.g., nitrogen, argon)

- Radiation symbol – Indicates radioactive materials

- Acid/ALK – Acidic or alkaline/corrosive properties

Typical Special Hazards Listed in the White Diamond

Special hazards can have a dramatic impact on how a chemical is handled during emergencies.

- Oxidizers (OX)

- Water-reactive substances (W̶)

- Corrosives (Acid, ALK)

- Radioactive materials

- Gases that can displace oxygen

Impact of Special Symbols on Emergency Procedures

The presence of a special hazard symbol fundamentally changes the approach of emergency responders and workers. For example, a water-reactive symbol signals that adding water could worsen a fire or cause an explosion, so alternative suppression methods are needed.

Emergency procedures must be tailored to these symbols, ensuring that workers know when to avoid certain interventions or to wear additional protective equipment. Proper identification of special hazards often prevents secondary accidents and saves lives.

Uses in Workplace Safety and Emergency Response

The hazardous materials diamond is found in diverse environments, from industrial facilities and laboratories to trucks transporting chemicals and public buildings storing cleaning agents. Its visible, standardized design makes it an essential tool for communicating hazards to anyone who may encounter potentially dangerous substances.

Workplace and Public Facility Applications

The diamond is used wherever chemicals are produced, stored, transported, or disposed of. Its presence on containers, storage areas, and entryways helps ensure that both employees and visitors are aware of potential dangers.

- Factories with chemical storage rooms

- Laboratories handling reagents and solvents

- Trucks transporting hazardous goods

- Maintenance closets in schools and hospitals

- Public utility sites with bulk chemicals

Utilization by Emergency Personnel

During an incident, first responders rely on the diamond to assess the scene and plan their approach. Its clear ratings and symbols enable firefighters, hazmat teams, and medical staff to make quick, informed decisions about evacuation, containment, and treatment.

Step-by-Step Procedure for Interpreting the Hazardous Materials Diamond in an Emergency:

- Approach from upwind and maintain a safe distance.

- Visually locate the hazardous materials diamond label on the affected container or area.

- Read each colored quadrant and note the numbers and any special symbols.

- Determine the highest hazard present (health, flammability, instability, or special hazard).

- Consult safety data sheets or emergency response guides for specific actions.

- Select appropriate personal protective equipment and containment strategies based on the hazard ratings and symbols.

- Alert others and initiate evacuation or isolation as necessary.

Regulatory Standards and Guidelines

The use of the hazardous materials diamond is governed by several regulatory agencies and standards to ensure consistent hazard communication and worker protection. These standards define where and how the diamond must be used, as well as the information it must display.

Responsible Agencies and Their Standards

Key agencies involved include:

- NFPA (National Fire Protection Association): Originator of the diamond system, standard NFPA 704.

- OSHA (Occupational Safety and Health Administration): Enforces hazard communication requirements in workplaces.

- DOT (Department of Transportation): Regulates labeling for hazardous materials in transit.

Key Standards and Legal Requirements

NFPA 704 Artikels the specific design, ratings, and placement requirements for the diamond. OSHA mandates clear, visible hazard communication on chemical containers and in work areas, often referencing NFPA or similar systems. DOT regulations ensure that hazardous materials are properly labeled during shipping and transportation.

| Agency | Standard | Application Area |

|---|---|---|

| NFPA | NFPA 704 | Fixed facilities, chemical storage, emergency planning |

| OSHA | Hazard Communication Standard (29 CFR 1910.1200) | Workplace labeling, training, and documentation |

| DOT | 49 CFR Parts 100-185 | Transportation of hazardous materials, vehicle placarding |

Real-World Examples and Case Studies

The hazardous materials diamond has played critical roles in preventing accidents and guiding emergency responses. Conversely, misinterpretation or lack of labeling has, at times, contributed to costly mistakes and injuries.

Examples of Incidents Where the Diamond Was Critical

Proper use and understanding of the hazardous materials diamond have made the difference in several real-world events:

- Firefighters avoided using water on a warehouse fire after noticing a water-reactive symbol, preventing a chemical explosion.

- A spill of concentrated acid in a public building was contained with the right protective gear thanks to clear health and corrosivity ratings on the diamond label.

- EMS personnel administered the correct first aid for chemical inhalation by checking the health rating before entering a laboratory accident site.

Scenario: Consequences of Misinterpretation

In a notable incident at a manufacturing facility, containers of an unstable chemical were incorrectly labeled, displaying a low reactivity number when the correct rating should have been 4. During a fire, responders assumed the material was stable and used standard firefighting methods. The result was a violent explosion, causing property damage and several injuries.

This case underscores the vital need for accurate labeling and thorough training.

Lessons Learned from Incidents

Incidents involving the hazardous materials diamond have highlighted several key takeaways:

- Accurate, up-to-date labeling saves lives and property.

- Training all personnel to understand the diamond is essential.

- Failure to recognize or act on special hazard symbols can lead to secondary disasters.

Best Practices for Implementation and Training

To maximize the effectiveness of the hazardous materials diamond, organizations must ensure that staff are properly trained and that labeling remains clear, accurate, and visible at all times.

Effective Training Methods

Comprehensive education is key to safe handling and emergency response. Training should cover the meaning of each color, rating, and symbol, as well as hands-on exercises for real-world scenarios.

- Classroom instruction on diamond components and hazard ratings

- Interactive workshops with mock labeling and interpretation drills

- Regular emergency response simulations and tabletop exercises

- Quizzes and assessments to confirm understanding

Guidelines for Maintenance and Label Visibility

Labels must be maintained to ensure they are legible and securely attached. Environmental factors, such as sunlight, chemicals, and abrasion, can fade or obscure labels over time.

- Use durable, chemical-resistant label materials

- Inspect labels during routine safety audits

- Replace damaged or faded labels immediately

- Ensure labels are placed at eye level and unobstructed

Checklist for Site Compliance and Inspection

A consistent inspection routine helps maintain high safety standards.

- Verify all containers have accurate, up-to-date diamonds

- Check label placement and visibility in all storage and use areas

- Ensure special symbols are applied where necessary

- Document inspections and corrective actions

- Review training records and schedule refresher courses

Conclusion

In summary, the hazardous materials diamond is much more than a simple label—it’s a compact, powerful tool that communicates critical safety information at a glance. By understanding its colors, numbers, and special symbols, everyone can contribute to safer workplaces and smarter emergency responses. As regulations evolve and industries grow, the diamond remains a constant reminder of the importance of clear communication and ongoing training in chemical safety practices.